With support from the Defense Health Agency J‐9 Research and Development (DHA R&D) Directorate, the Steve Badylak Laboratory at the McGowan Institute for Regenerative Medicine at the University of Pittsburgh is developing a lightweight, portable and temperature-tolerant hydrogel that can be used at the point-of-care in a wide range of military operations, including rapid clotting in low pressure bleeds. In fact, this technology has led to the establishment of a new company – ECM Therapeutics. This project was funded through MTEC’s Request for Project Proposals for developing production‐ready prototypes of regenerative medicine based therapies (Solicitation #19-07-Biomfg).

Hydrogels, which are highly hydrated polymer materials, composed of extracellular matrix (ECM) have been shown to improve immunomodulatory activity, recruit endogenous stem/progenitor cells to the anatomic site of placement, and promote the replacement of injured or missing tissue. However, clinical translation of ECM hydrogels, including for battlefield point-of-care, depends on development of large-scale manufacturing techniques and a resulting product that is readily sterilized, portable, has a robust shelf life at a range of temperatures, and can meet industry standards for safety and efficacy. Current commercially-available surgical hemostats often require restrictive storage conditions and/or lengthy preparation procedures that are difficult for untrained personnel. In contrast, the point-of-care ECM hydrogel presented here is a stable, off-the-shelf formulation that is ready-to-use with little training or preparation; and can be easily administered to initiate rapid and sustained hemostasis.

Since the start of the MTEC award, the Badylak Lab has:

- developed and validated a cost-effective, proprietary cGMP manufacturing strategy for their point-of-care ECM hydrogel,

- identified FDA-approved methods for packaging and sterilization of the ECM hydrogel,

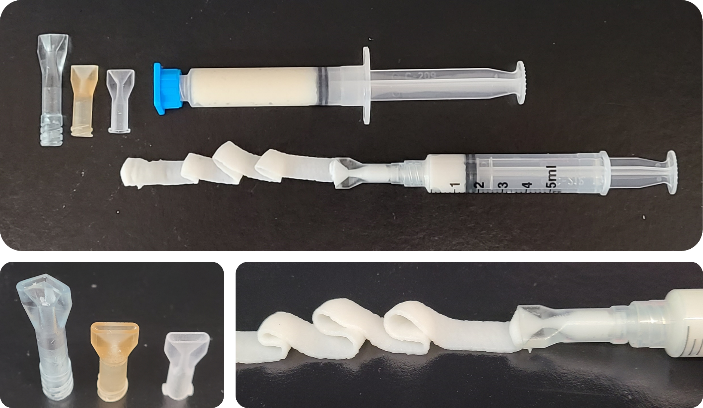

- designed a wide-mouth, luer-locking applicator tip which allows for more precise application of the ECM hydrogel to the sites of bleeding, and

- demonstrated the robust in vitro and in vivo hemostatic properties of the ECM hydrogel.

The ECM hydrogel is lightweight, portable, and temperature tolerant and can be used in a wide variety of military operations including stopping the flow of blood in traumatic battlefield injuries. Through their cGMP scale-up process, 1000 syringe batch runs have been completed.

Moreover, using non-MTEC funds, the Badylak lab completed preclinical liver laceration studies which showed that the ECM hydrogel can initiate rapid clot formation in a high volume, low pressure bleed. Importantly, the hydrogel can be easily removed after cessation of bleeding. Additionally, the hydrogel formulation has other potential therapeutic applications beyond routine surgical procedures including its use in acute traumatic soft tissue injuries, bulk tumor resection, and whole organ hemorrhage.

The Badylak Lab has completed packaging requirements for their ECM hydrogel. Shown here is the hydrogel after sterilization in its final packaging. Following this, preclinical testing was performed in a rodent liver laceration model to evaluate clotting time in a low-pressure bleed.

With the ability to cGMP manufacture large-scale clinical batches of ECM hydrogel, the next step in this project is to advance to Phase I clinical trials. This effort includes meeting FDA regulatory requirements for Class III medical devices by conducting animal performance testing and formal ISO 10993 testing, followed by clinical safety and efficacy trials in a 10-patient study.

About the Badylak Laboratory at the University of Pittsburgh:

The Steve Badylak Laboratory at the University of Pittsburgh has significant expertise in ECM structure and function. More than 70 patented ECM-based technologies originating in this laboratory have resulted in the treatment of more than 12 million patients. The emphasis upon clinical translation has resulted in the establishment of several companies including ECM Therapeutics – the industry partner that played a major role in developing a method to upscale manufacture an ECM hydrogel. Special thanks to Dr. George Hussey who conducted the majority of benchtop and in vivo studies in completion of this work.